Rotary Cylinders

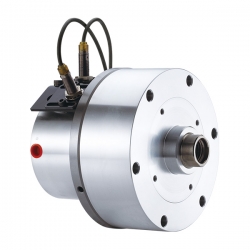

Looking for a reliable supplier of rotary cylinders to enhance your automation processes? AUTOGRIP® has got you covered. Our rotating hydraulic cylinders are specifically designed to work with high-speed rotation of the spindle to drive the clamping and loosening of the chuck, making them an essential component in the automatic clamping configuration.

We offer two types of rotary cylinders, including rotary hydraulic cylinders and rotary air cylinders. Our hydraulic rotary cylinders come equipped with a built-in non-return valve self-locking mechanism, providing the function of central air injection or water injection, depending on the model. They can also be used with a stroke detection mechanism to ensure accurate positioning of the workpiece clamping.

Autogrip® Full range of Rotary Cylinders is recommended to you below, we strive to provide high-quality products that meet the needs of our clients, and we are also looking for agents, welcome to join us now.

- Built-in check valve with self-locking mechanism: Ensures secure workpiece clamping even in case of pressure source failure or pipe damage. Enhances operational efficiency and safety.

- Pressure relief valve: Prevents system overpressure, safeguarding the hydraulic cylinder from damage. Extends equipment lifespan and improves reliability.

- Linear positioning sensing system: Supports full stroke detection, with clamping positions set via Teach-in without manual adjustment. Enhances clamping precision, reduces downtime for quick setup, and increases operational efficiency and productivity.

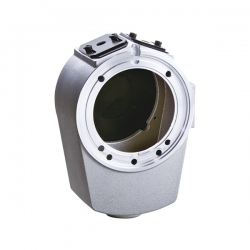

- Cylinder Barrel: Supports internal pressure and contains hydraulic fluid.

- Piston and Piston Rod: The piston moves within the cylinder barrel to generate rotary motion, and the piston rod transmits this motion to external mechanisms.

- Seals: Prevent hydraulic fluid leakage and maintain pressure within the system.

- End Caps: Seal the ends of the cylinder barrel and provide attachment points for mounting the hydraulic actuator.

- Built-in Check Valve: Automatically locks in case of pressure source failure to prevent sudden pressure drops.

- Pressure Relief Valve: Regulates and controls internal pressure to prevent overpressure.

- Rotating Joint: Allows hydraulic fluid to flow in and out of the hydraulic actuator during rotation.

- Linear Sensor (optional): Provides precise position feedback by detecting piston stroke and holding positions.

- Hydraulic Energy Transmission: Hydraulic oil is pressurized by the hydraulic pump and transmitted through pipelines into the interior of the hydraulic rotary cylinder.

- Piston Movement: After hydraulic oil enters the hydraulic cylinder, it drives the piston inside the cylinder. The piston of the hydraulic cylinder is typically connected to a rack-and-pinion mechanism or a screw mechanism.

- Conversion to Rotary Motion: The linear motion of the piston is converted into rotary motion either through a rack-and-pinion mechanism or through a screw mechanism.

- Rotary Output: The converted rotary motion is then outputted for tasks such as clamping and releasing components or other rotational operations.

- Ensuring Optimal Performance:

- Maintaining operational efficiency: Regular cleaning and lubrication of pneumatic or hydraulic rotary actuators ensure smooth operation of internal moving parts, reducing friction and resistance, thus improving operational efficiency.

- Preventing failures: Regular inspection and replacement of worn components allow timely detection and resolution of potential issues, preventing unexpected failures and ensuring continuous stable operation of equipment.

- Extending Service Life:

- Minimizing wear: Regular maintenance effectively reduces damage caused by friction and wear, thereby extending the service life of pneumatic or hydraulic rotary actuators.

- Preventing corrosion: Timely cleaning prevents oil contamination and impurities from causing corrosion to pneumatic or hydraulic rotary actuators, protecting their surface and internal structure.

- Enhancing Safety:

- Preventing accidents: During maintenance, checking safety devices such as check valves and pressure relief valves ensures their proper operation, preventing safety incidents caused by malfunctions.

- Maintaining stability: Regular inspection of clamping mechanisms and positioning systems ensures secure clamping and precise positioning of workpieces, preventing workpiece detachment or misalignment.

- Regular inspection and replacement of hydraulic oil:

Check the quality and level of hydraulic oil regularly. Replace aged or contaminated hydraulic oil promptly to keep the system clean internally.

- Lubrication and cleaning:

Regularly lubricate moving parts to reduce friction. Clean the surface of the cylinder body to prevent accumulation of dust and oil stains.

- Inspection of seals:

Check the condition of seals. Replace worn or aged seals promptly to prevent hydraulic oil or compressed air leaks.

- Testing of safety devices:

Periodically test safety devices such as check valves, pressure relief valves, and positioning systems to ensure they operate correctly.

- Maintenance record keeping:

Maintain detailed maintenance records to track the content and results of each maintenance session. This helps in predicting and scheduling future maintenance tasks.